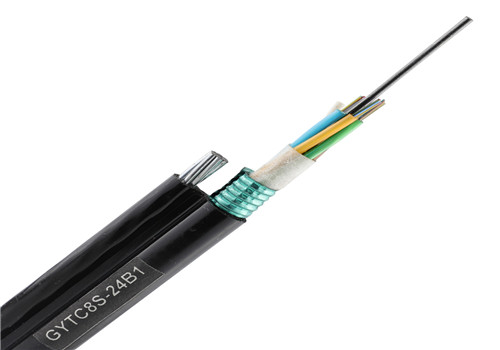

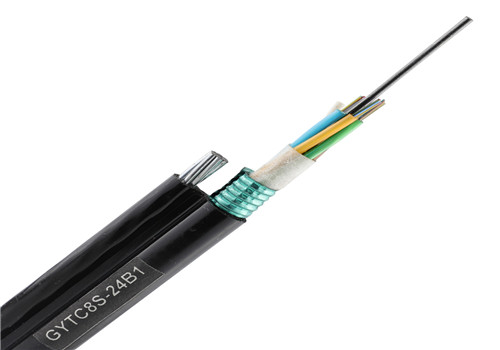

The loose tube are made of high modulus plastic (PBT), which are filled with water resistant gel. The corrugated

steel tape is applied which provide for crush resistant. Outer sheath is made of UV resistance PE jacket. Figure-8 self-supporting structure provide high tensile strength and enables easy and cost saving aerial installations.

Features:

Application:

For hanging on poles.

Structure and Technical Specifications

|

Fiber Count |

8-30 |

32-60 |

62-72 |

74-96 |

98-120 |

122-144 |

|||||

|

Diameter of Self support member (Steel wire) |

7x0.9, 7x1.0, 7x1.2, 7x1.4 , 7x1.6 |

||||||||||

|

Diameter of Loose tube(mm) |

1.8 |

2.1 |

2.1 |

2.1 |

2.1 |

2.1 |

|||||

|

Diameter of Cable(mm) |

8.1 |

8.7 |

9.3 |

10.6 |

11.9 |

13.4 |

|||||

|

Gross weight(Kg/Km) |

— |

— |

— |

— |

— |

— |

|||||

|

Min. bending radius |

Static 10xD Dynamic 20xD |

||||||||||

|

Diameter of Self support member (Steel strand wire) mm |

7x0.9mm |

7x1.0mm |

7x1.2mm |

7x1.4mm |

7x1.6mm |

||||||

|

Max. tensile force, N Short term |

3000 |

4000 |

6000 |

8000 |

12000 |

||||||

|

Max. tensile force, N Long term |

1000 |

1500 |

2000 |

3000 |

5000 |

||||||

|

Max Crush Resistance(N/100mm) |

Short term 1000N |

||||||||||

|

Long term 300 N |

|||||||||||

|

Allowable Temperatures |

operation |

-40°C – +60°C |

|||||||||

|

storage |

-50°C – +70°C |

||||||||||

|

install. |

-20°C – +50°C |

||||||||||